|

PRINCIPAL PARTICULAR

LENGTH (O.A)

..........................

... ABT.

.....

.. 163.08 m

LENGTH (P.P)

..........................

...

......

.

152.45 m

BREADTH (MLD)

..........................

.............

26.00 m

DEPTH (MLD)

...........................

......

14.25 m

DRAFT (MLD) DESIGNED

..........................

......

9.80 m

DEAD WEIGHT

..........................

. ABT.

......

..

25,000

M.T

CARGO HOLD VOLUME

....

.........................

. 32,800 m3

CARGO GEAR

.

..........................

....

..

4 x 30 Tone

MAIN ENGINE AKASAKA MITSUBISHI

6UEC43LSII

.........................

... 6300KW x 160

SPEED SERVICE (85% OUTPUT)

........................

. ABT.

......

.. 13.2

COMPLEMENT

.......................

.....

..

30P

CLASS

..............................

...

BV

NAVIGATION AREA

.......................

......

. OCEAN

GOING

NOTATION CLASS (PRELIMINARY):

I HULL MACH, BULK CARRIER, BC-A, CSR, ESP NON HOM LOAD (CH 2 AND

CH 4 MAY BE EMPTY), GRAB(20).

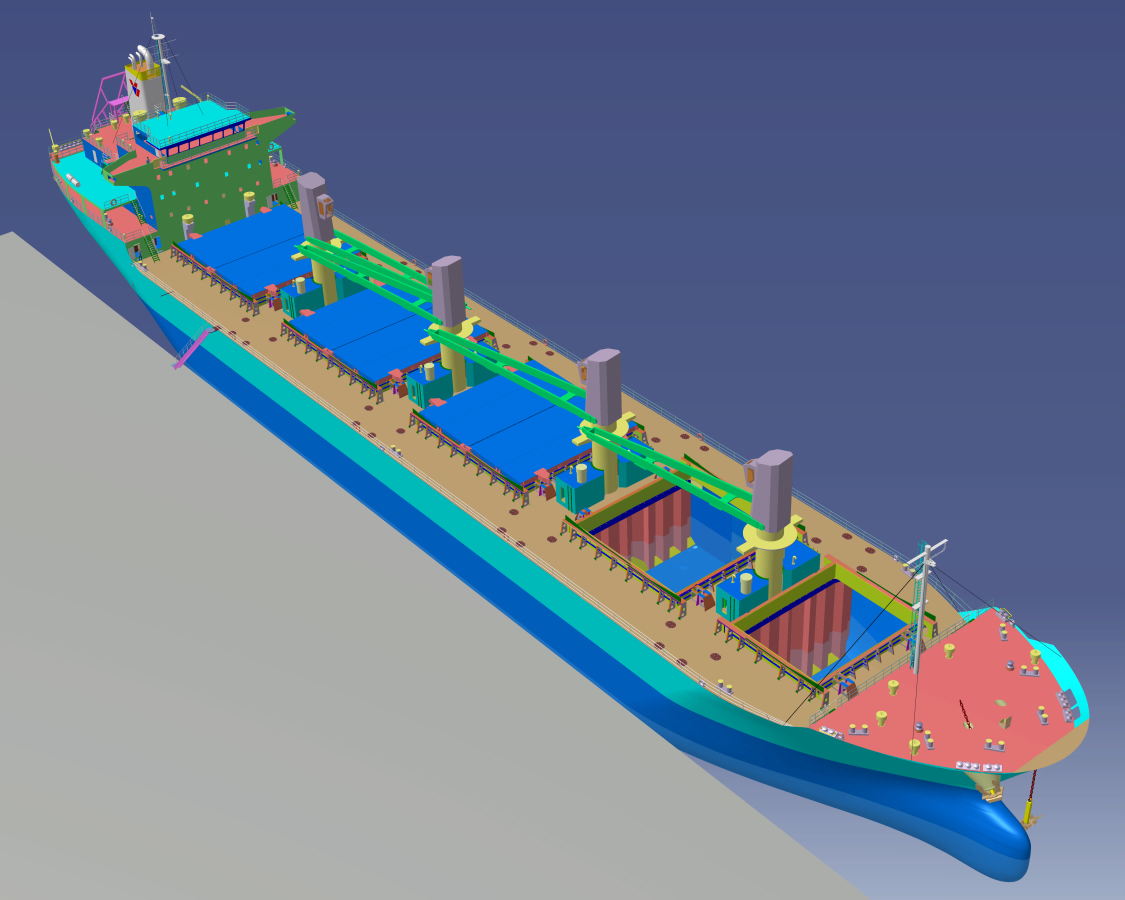

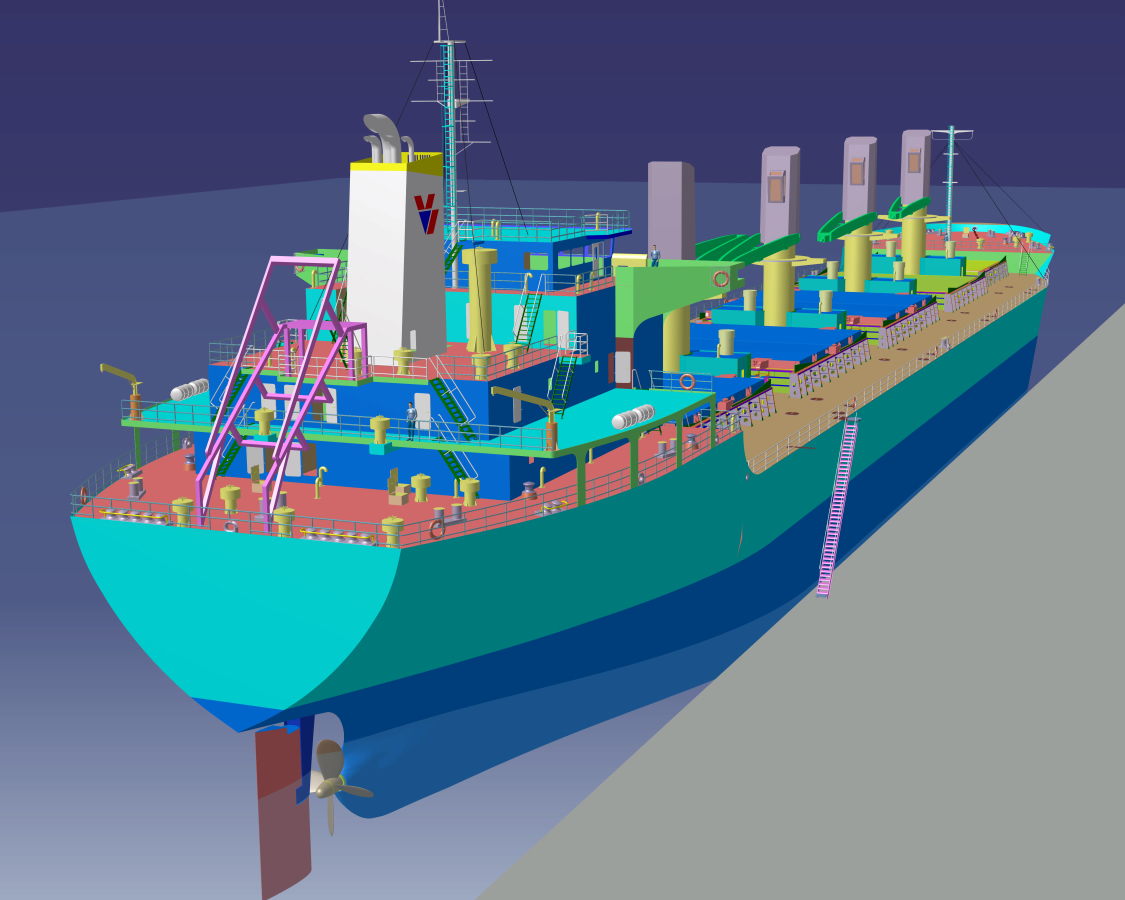

GENERAL MODEL OF 25,000 DWT BULK CARRIER

GENERAL MODEL OF 25,000 DWT BULK CARRIER (Continue)

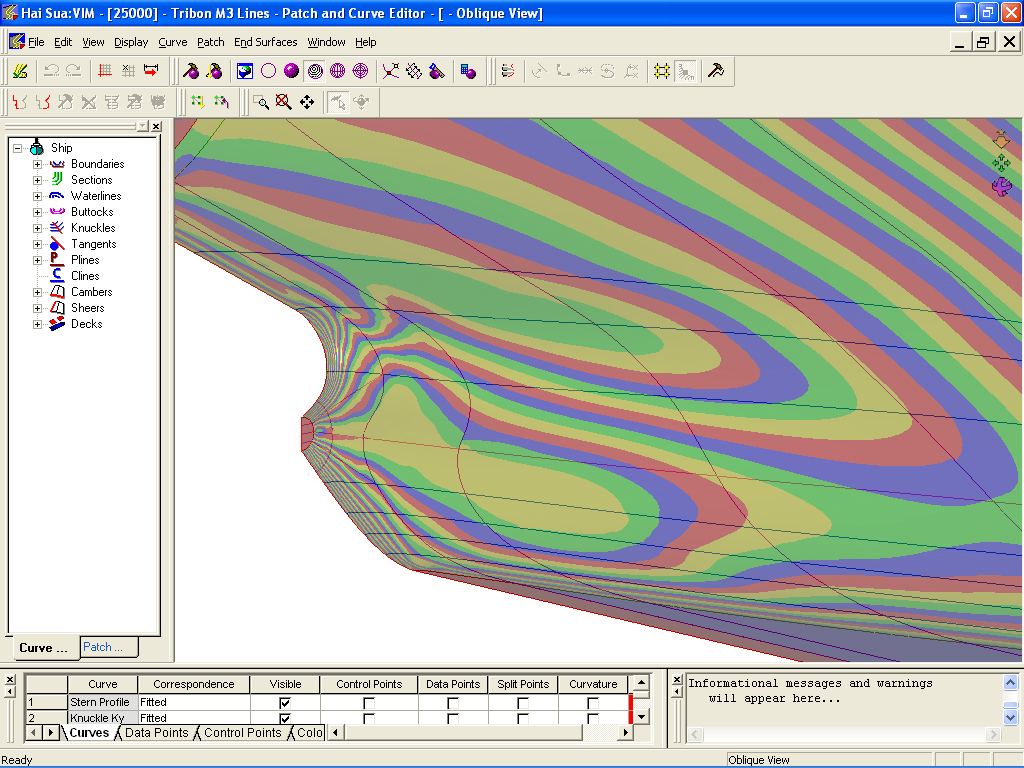

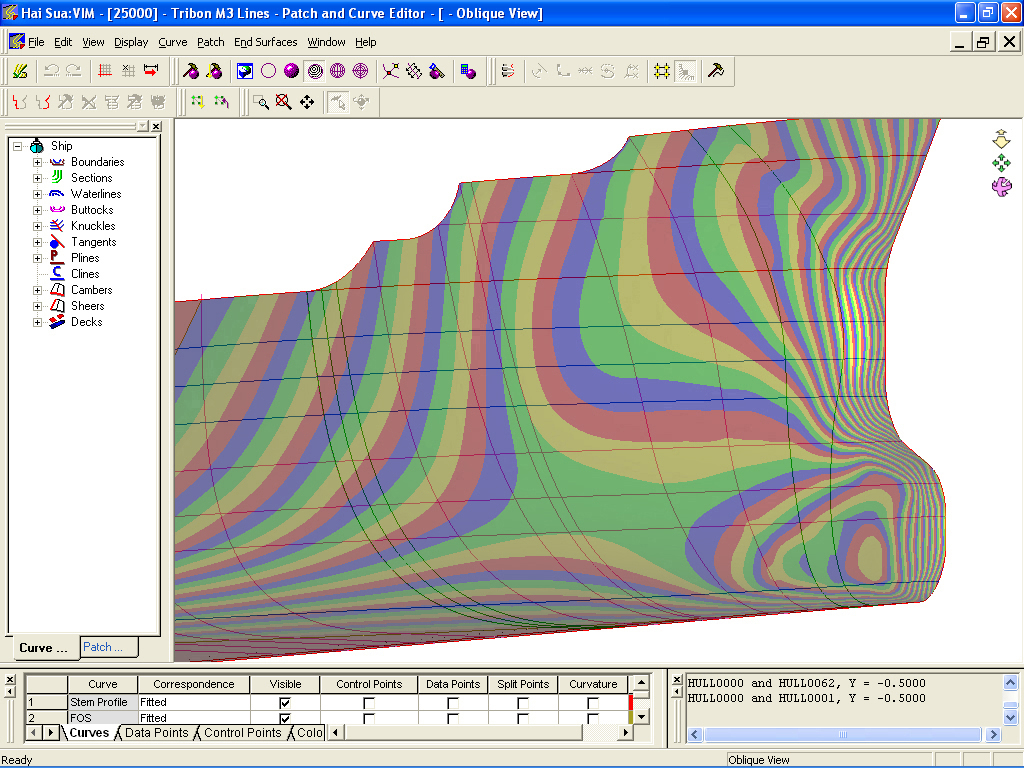

USING THE TRIBON PROGRAM TO LINES

USING THE TRIBON PROGRAM TO LINES (Continue)

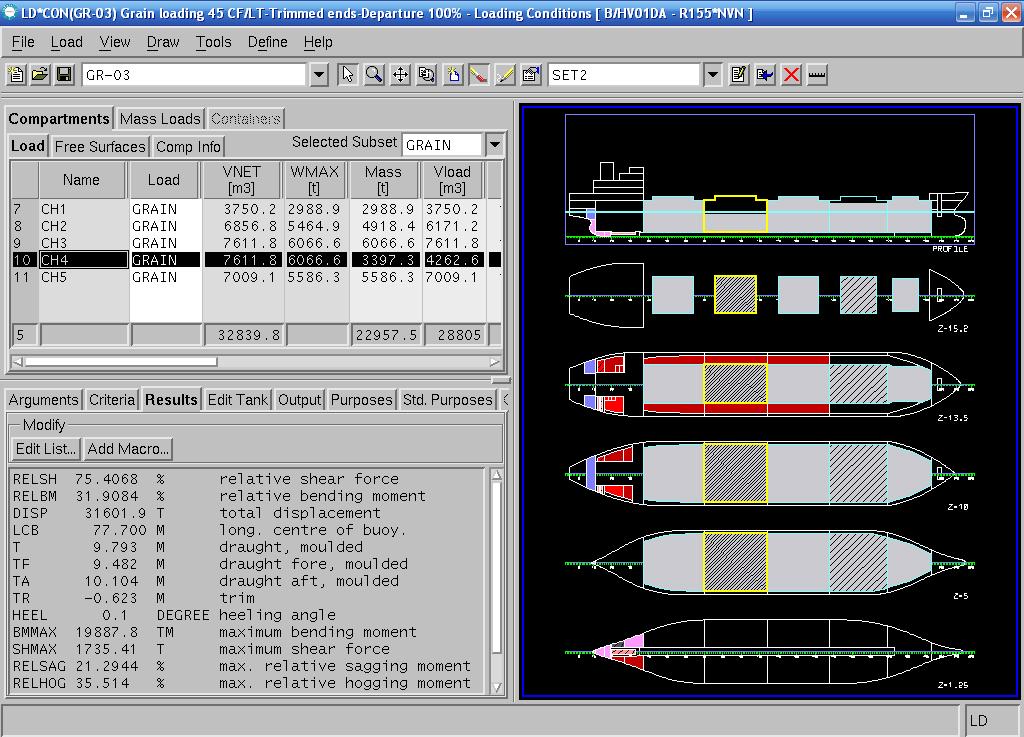

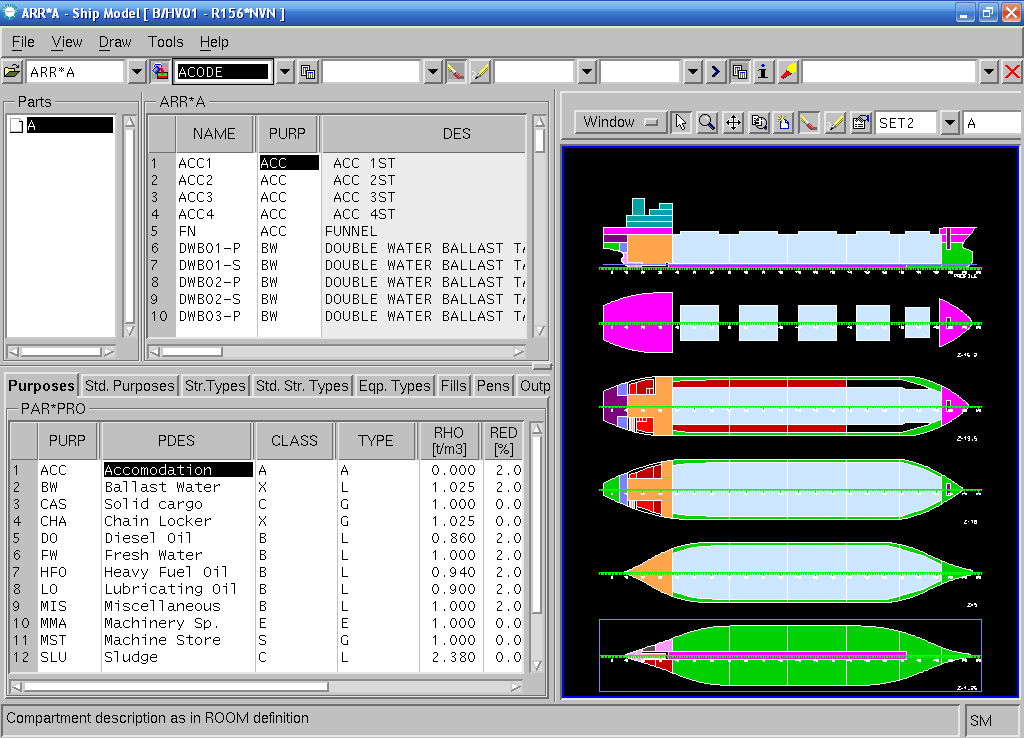

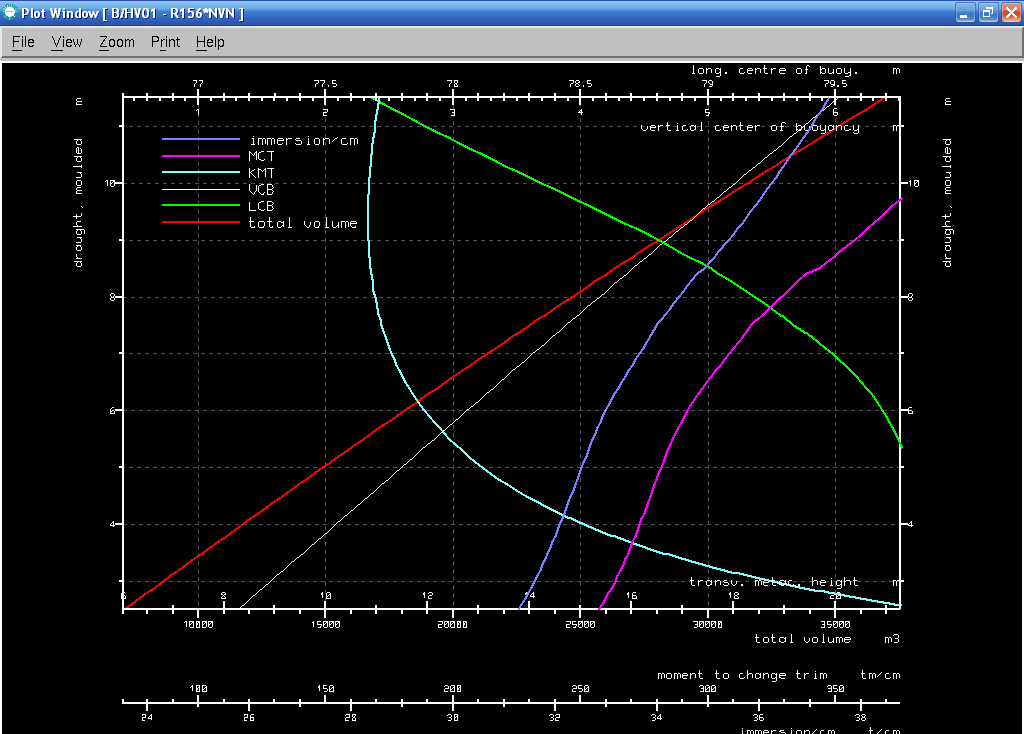

USING THE NAPA PROGRAM TO CALCULATE THE STABILITY

USING THE NAPA PROGRAM TO CALCULATE THE STABILITY (Continue)

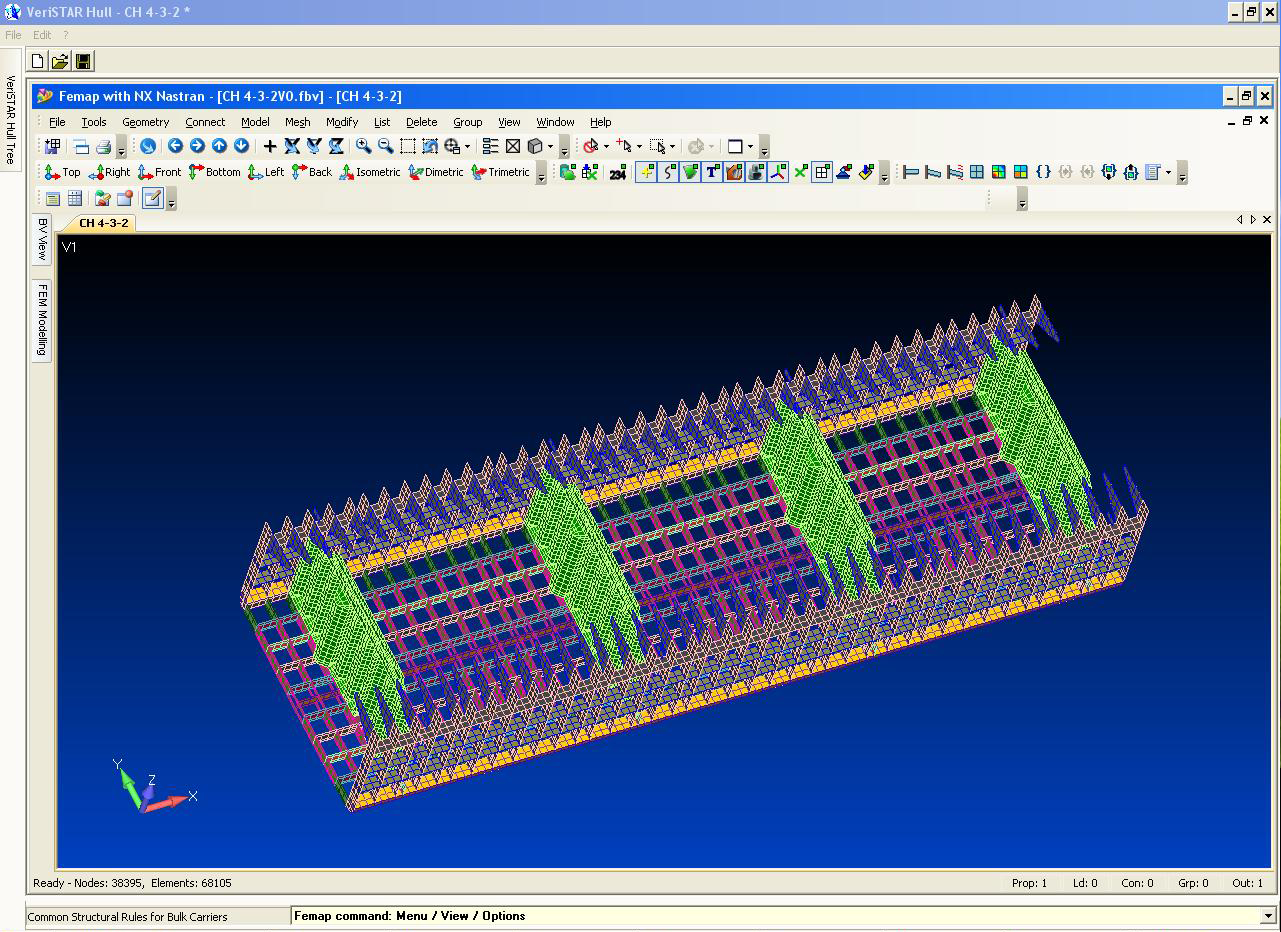

USING THE VERISTAR PROGRAM TO ANALYSIS OF THE SHIPS STRUCTURAL

USING THE VERISTAR PROGRAM TO ANALYSIS OF THE SHIPS STRUCTURAL

(Continue)

USING THE VERISTAR PROGRAM TO ANALYSIS OF THE SHIPS STRUCTURAL

(Continue)

THE VERISTAR HULL SORFTWARE FOR CSR

Ø

Fast modeling tool

Ø

Automatic corrosion deduction

Ø

Automatic loading conditions

Ø

Automatic criteria

checking : Yielding ratio ; Bukling ratio; Fatigue

THE ANALYSIS RESULTS

Ø

Strength analysis

Ø

Bukling analysis

Ø

UC check

Ø

Fatigue analysis

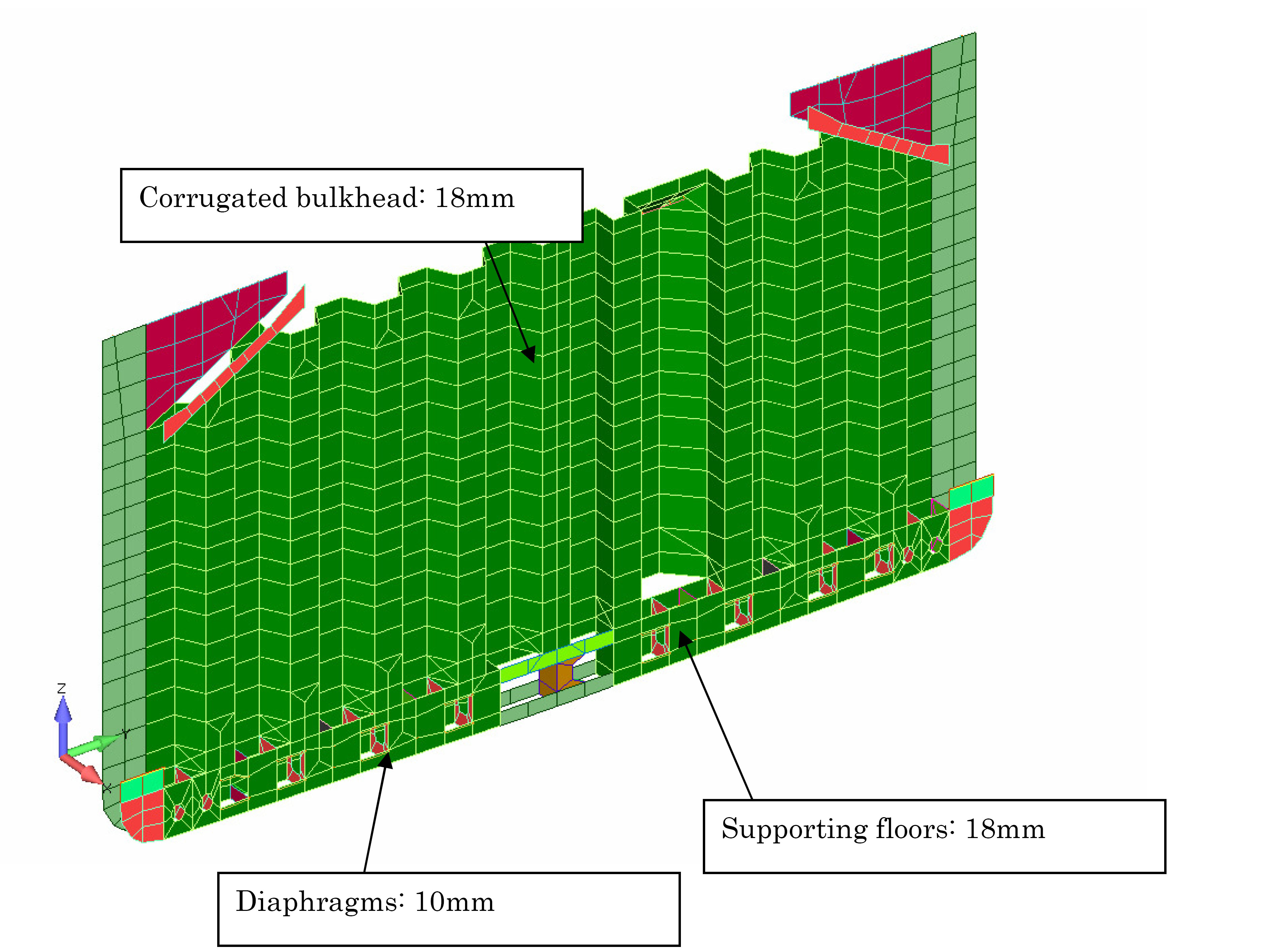

Corrugated bulkhead thickness

and supporting floor thickness and openings FR 70 and 169

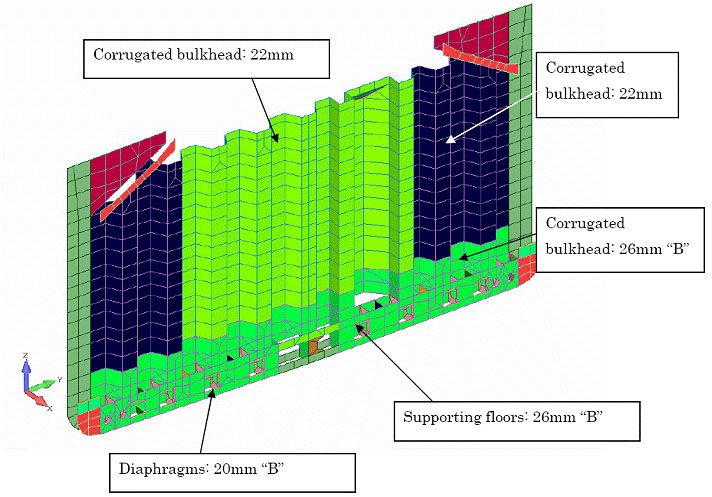

Bulkhead

FR 104 and 138 Bulkhead

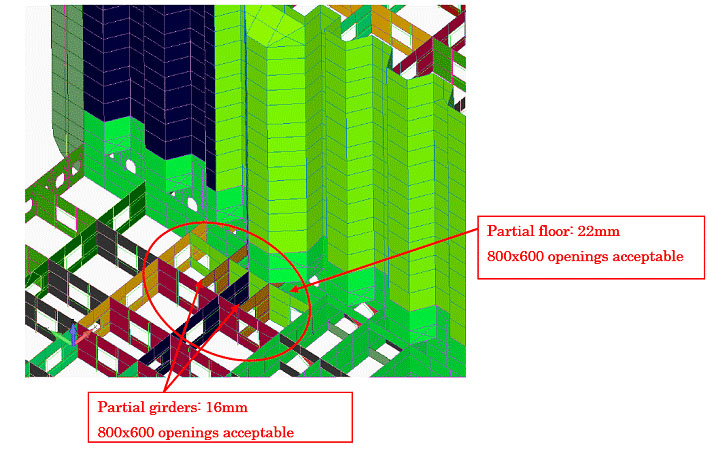

Reinforcement under inner bottom

in way of spiral ladder install position

Partial floor and partial girders to be provided as follows

between FR101/135 and FR104/138

Partial floor to be provided as follows between FR67/166 and

FR70/169

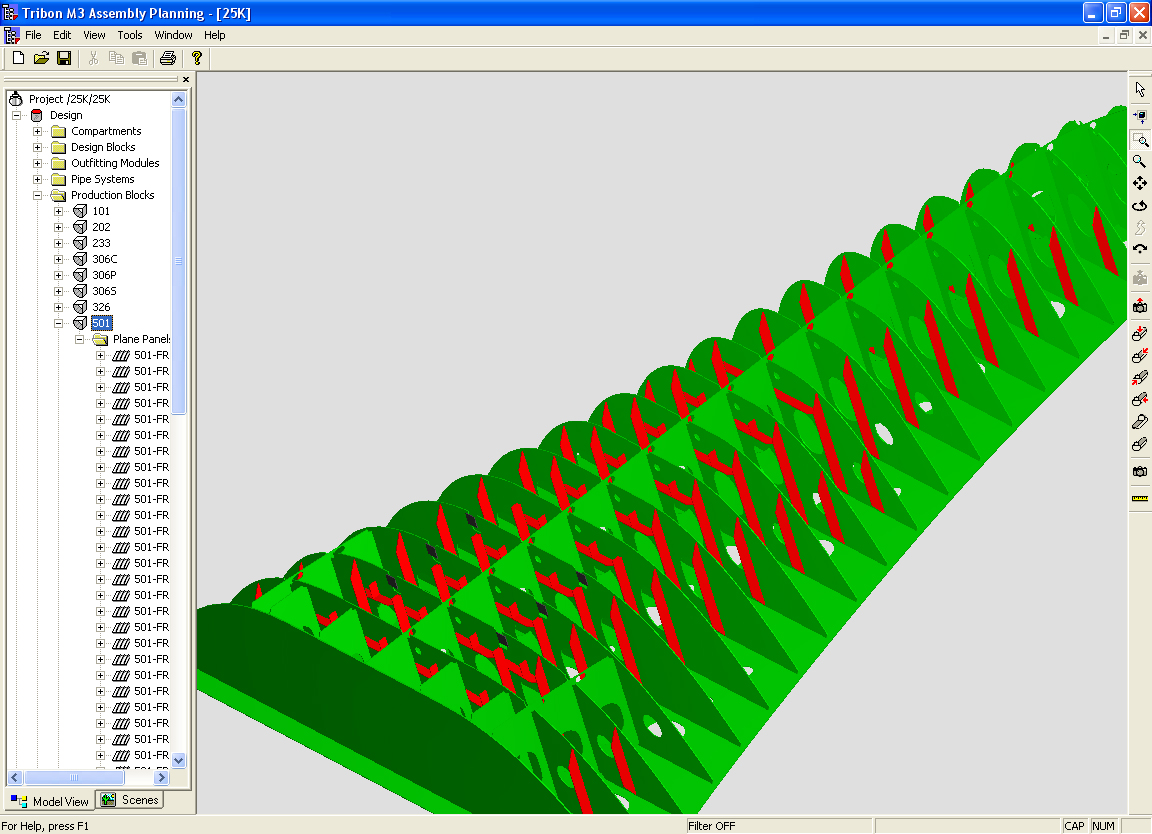

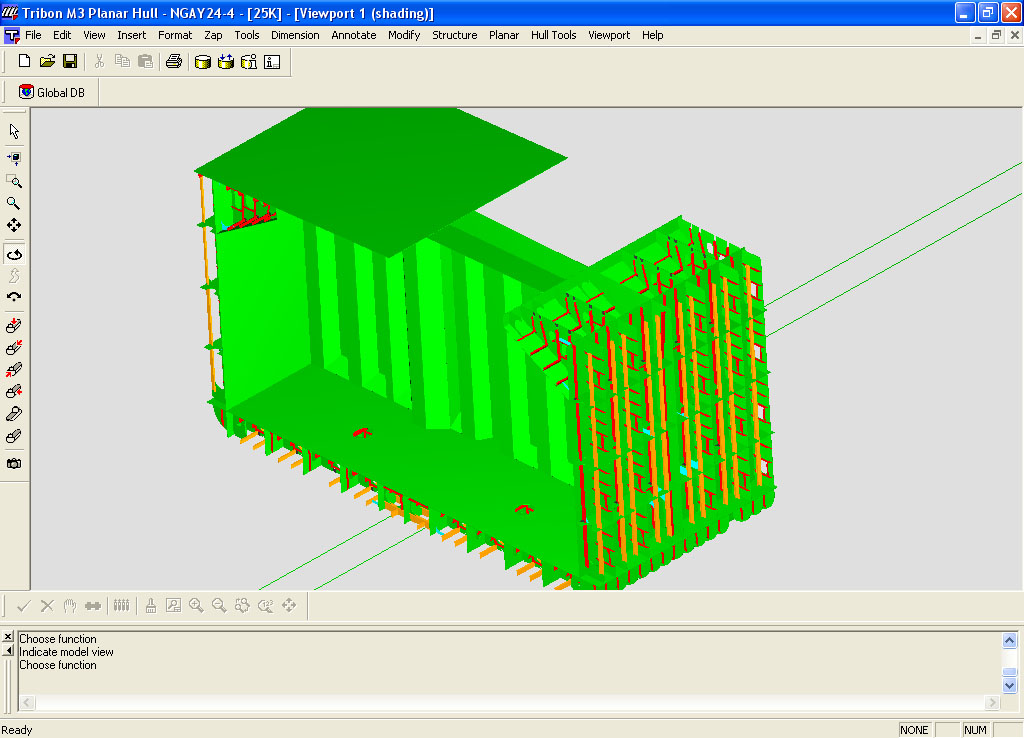

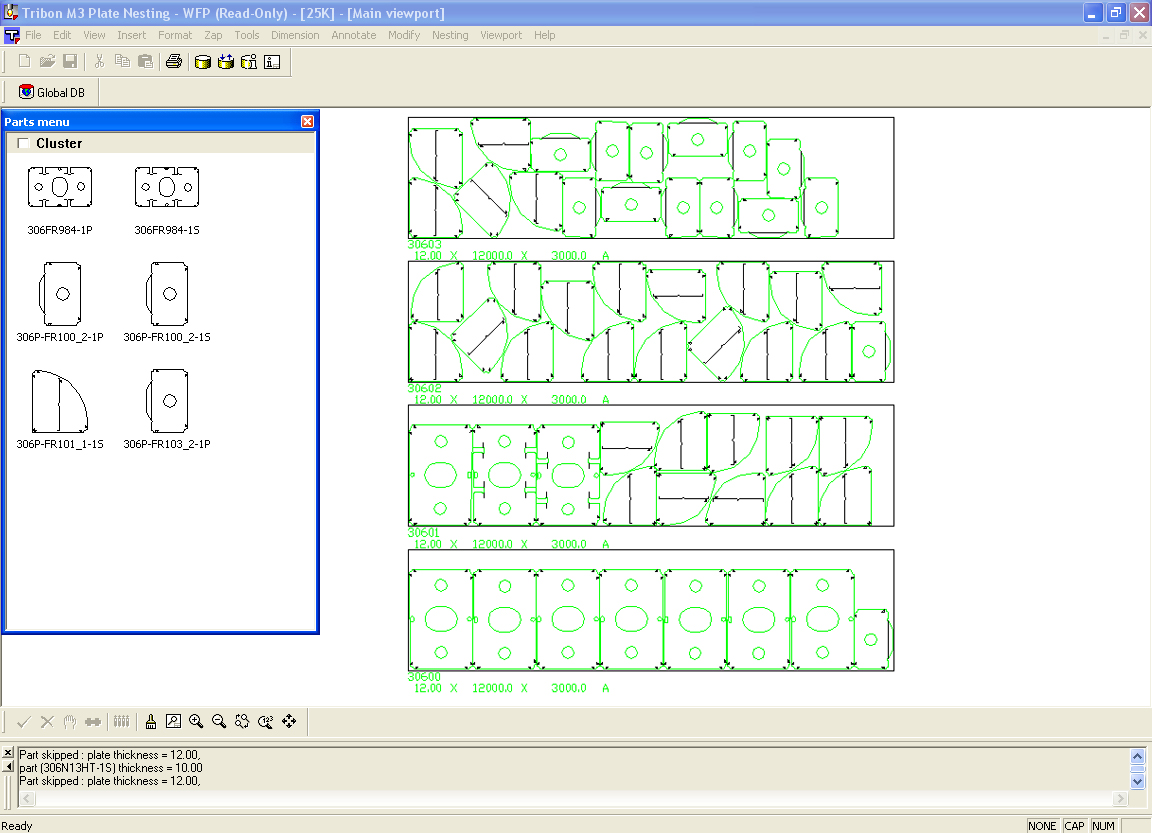

FABRICATION DESIGN USING THE TRIBON PROGRAM

FABRICATION DESIGN USING THE TRIBON PROGRAM (Continue)

FABRICATION DESIGN USING THE TRIBON PROGRAM (Continue)

FABRICATION DESIGN USING THE TRIBON PROGRAM (Continue)

|